Ճնշման փորձարկումը մեծ դեր է խաղում հիդրավլիկայում՝ ապահովելով, որ խողովակները, ռետինե խողովակները և բաքերը իսկապես կարողանան կատարել դաշտում տեսնվող աշխատանքը: Այսօր մենք կանդրադառնանք, թե ինչու են այս փորձարկումները կարևոր, ինչպես են մարդիկ դրանք կատարում և ինչպես կարող է փորձարկումը հաջողությամբ հանձնելը խնայել ժամանակ և գումար յուրաքանչյուր աշխատանքում:

Հիմնարար նպատակը՝ պաշտպանել հիդրավլիկ համակարգի ամբողջականությունը

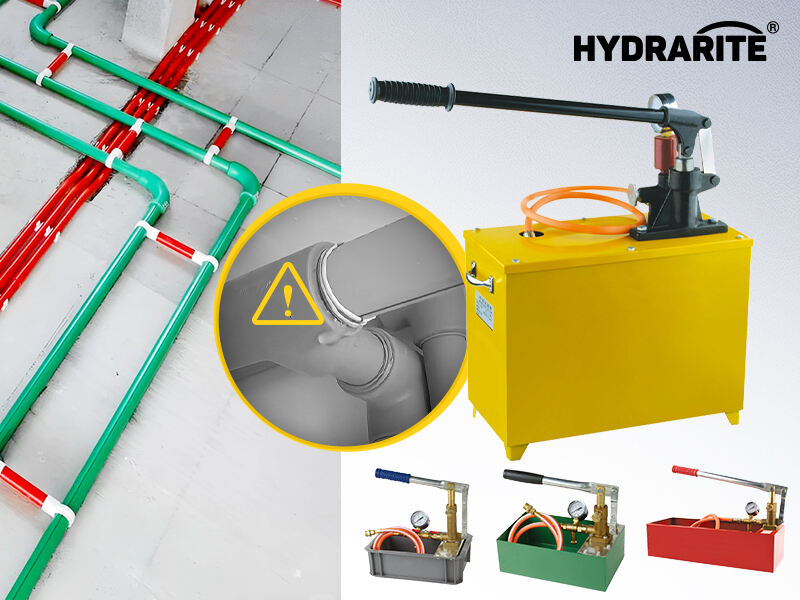

Ըստ էության, ճնշման փորձարկումը վերջնականապես համոզվում է, որ հիդրավլիկ համակարգի բոլոր մասերը բավարար ամրություն ունեն բեռը կրելու համար: Մեխանիկները շղթան լցնում են հեղուկով կամ գազով, մեծացնում են ճնշումը և հսկում են արտահոսքերը կամ լցվածքները: Խնդիրները խանութում հայտնաբերելը նշանակում է, որ ավելի քիչ վթարներ են տեղի ունենում շինարարական հրապարակներում, այնպես որ պոմպը, աստիճանը և վինչը աշխատում են վստահությամբ: Այս գործընթացը ուղղված է ոչ միայն ակնհայտ թերությունների հայտնաբերմանը. այն նաև բացահայտում է նյութերի միկրոսկոպիկ թուլությունները, որոնք ժամանակի ընթացքում կարող են վատանալ անընդհատ ճնշման տակ: Ճնշման փորձարկումը՝ իրական աշխարհի շահագործման պայմանների մոդելավորման միջոցով, ապահովում է, որ նույնիսկ ամենափոքր բաղադրիչները, ինչպես օրինակ O-օղակները և վալվերը, կարողանան դիմանալ ամենօրյա օգտագործման լարվածությանը:

Տարածված փորձարկման մեթոդներ՝ հիդրոստատիկ և պնևմոդինամիկ

Ամենատարածված փորձարկումը՝ հիդրոստատիկ փորձարկումը, ավելացնում է ջուր, մինչև շղթան լիքը լինի, ապա դանդաղ ճնշումը բարձրացնում է սովորականից զգալիորեն ավելի բարձր: Քանի որ ջուրը գործնականում չի սեղմվում, նույնիսկ ամենափոքր արտահոսքերը արագ են հայտնվում, թույալ տալով անձնակազմին անմիջապես նշել վերացնելու վայրերը: Այս մեթոդը հատկապես արդյունավետ է հեղուկներ կառավարող համակարգերի համար, քանի որ մոդելավորում է նրանց վարքը: Օգտակար կարող է լինել նաև պնևմոնիկ փորձարկումը, հատկապես խորանիստ տարածություններում, սակայն քանի որ ազատված օդը մեծ չափով ընդարձակվում է, այն պահանջում է զգույշ պաշտպանություն, չափիչ սարքեր և հանգիստ թիմ: Պնևմոնիկ փորձարկումը հաճախ ընտրվում է գազեր փոխադրող համակարգերի համար կամ այն դեպքերում, երբ ջրի մնացորդները կարող են վնաս հասցնել, ինչպես օրինակ՝ սննդի մշակման սարքավորումների հիդրավլիկ համակարգերում: Յուրաքանչյուր մեթոդ ունի իր եզակի առավելությունները, և ճիշտ մեկը ընտրելը կախված է համակարգի դիզայնից և նախատեսված օգտագործումից:

Անվտանգությունից Ավել: Համապատասխանություն և Ծախսերի Տնտեսում

Ճնշման փորձարկման առավելությունները հեռու են գնում այն բանից, որ ամեն ինչ պայթեցնելուց խուսափենք: Կառուցարաններում, արտադրության և նավթագազային ճյուղերում այդ փորձարկումների հաջող անցկացումը ցույց է տալիս կարգավորողներին և հաճախորդներին, որ ընկերությունը կանոններին հետևում է: Այդպիսի հեղինակությունը կրճատում է իրավական խնդիրները և բարելավում է ընկերության պատկերը՝ որպես այնպիսի խանութ, որն ապրանքի որակի մասին հոգևորում է: Ավելին, հետազոտությունների կանոնավոր անցկացումը խնայում է մեծ գումար, քանի որ հայտնաբերում է թուլակետերը այն բանից, քան դա կարող է կանգնեցնել արտադրությունը կամ առաջացնել թանկարժեք վերանորոգումներ: Օրինակ, արտադրական գործարանում անջատված հիդրավլիկ բաղադրիչը կարող է ամբողջ արտադրական գիծը կանգնեցնել, ինչը կարող է դադարի ընթացքում հազարավոր դոլարներ պահանջել: Ճնշման փորձարկումները օգնում են խուսափել այդպիսի իրավիճակներից՝ հայտնաբերելով խնդիրները վաղ:

Տեխնոլոգիական նորամուծություններ. Փորձարկումները դարձնելով ավելի խելացի

Նոր տեխնոլոգիաները ճնշման փորձարկումը վերածել են ավելի արագ և համեմատաբար հեշտ աշխատանքի։ Ամբողջությամբ ավտոմատացված սարքավորումները բացառում են մարդկային սխալները՝ կատարելով ստուգումներ ճշգրիտ արդյունքներով և ավարտելով աշխատանքը ժամանակի մի փոքր մասում: Սենսորների ավելացումը, որոնք իրական ժամանակում տվյալներ են ուղարկում ինժեներների էկրաններին, թույլ է տալիս թիմերին ճշգրտել մեքենաները կամ պլանավորել նույն պահին վերանորոգումները, երբ ցուցանիշներից մեկը շեղվում է սահմանված արժեքից: Այս նվաճումները հնարավորություն են տալիս նաև հեռական հսկողության իրականացման, ինչն էլ մասնագետներին հնարավորություն է տալիս հսկել փորձարկումները աշխարհի ցանկացած վայրից: Բացի այդ, փորձարկող սարքավորումների հետ ինտեգրված ծրագրաշարն ընդունակ է վերլուծել նախորդ տվյալները՝ կանխատեսելով այն պահը, երբ սարքավորումների մասերը կարող են վնասվել, ինչը թույլ է տալիս կանխահարձակ պլանավորված նորոգումներ իրականացնել և ավելի շատ նվազեցնել ծախսերը:

Ապագայի հեռանկարը՝ հիդրավլիկայում աճող նշանակություն

Ապագայում հիդրավլիկայում ճնշման փորձարկման դերը անհրաժեշտաբար աճելու է: Հիդրավլիկ համակարգերը ավելի բարդանում են, և քանի որ ղեկավարները սեղմում են ավելի խիստ անվտանգության սահմանների վրա, կհետևեն ավելի խիստ փորձարկման կանոններ: Ընկերությունները, որոնք ճնշման փորձարկումը դիտում են որպես պարտադիր գործողություն, այլ ոչ թե հնարավորություն, կարող են իրենց սարքավորումները ավելի երկար պահել գործող վիճակում և առաջ անցնել արագ փոխվող շուկայում: Ինտելեկտուալ արտադրության և Արդյունաբերություն 4.0-ի աճի հետ մեկտեղ ճնշման փորձարկումը ավելի խորապես կինտեգրվի այլ համակարգերի հետ, ապահովելով իրական ժամանակում հետադարձ կապ, որն օպտիմալացնում է սարքավորումների ընդհանուր արդյունավետությունը: Այս ինտեգրումը հիդրավլիկ համակարգերին կդարձնի ավելի հուսալի, արդյունավետ և անվտանգ, քան այդ պահին:

Որպես ամփոփում՝ ճնշման փորձարկումը անհրաժեշտ մաս է մնում ցանկացած հիդրավլիկ համակարգի անվտանգ աշխատանքը ապահովելու համար: Երբ ձեռնարկությունները տիրապետում են ճիշտ փորձարկման մեթոդներին, նրանք պաշտպանում են իրենց սարքավորումները, համապատասխանում են օրինական չափանիշներին և ապահովում են ամենաբարձր արդյունավետությունը: Քանի դեռ տեխնոլոգիաները զարգանում են, այդքան ավելի մեծ նշանակություն կունենա ճնշման փորձարկումը՝ ապահովելով, որ հիդրավլիկ համակարգերը կարողանան համապատասխանել ժամանակակից արդյունաբերության պահանջներին:

Բովանդակության աղյուսակ

- Հիմնարար նպատակը՝ պաշտպանել հիդրավլիկ համակարգի ամբողջականությունը

- Տարածված փորձարկման մեթոդներ՝ հիդրոստատիկ և պնևմոդինամիկ

- Անվտանգությունից Ավել: Համապատասխանություն և Ծախսերի Տնտեսում

- Տեխնոլոգիական նորամուծություններ. Փորձարկումները դարձնելով ավելի խելացի

- Ապագայի հեռանկարը՝ հիդրավլիկայում աճող նշանակություն