Flange spreaders are must-have tools for anyone who works on heavy equipment with flanged connections. Built to pry apart two flange surfaces, they give technicians safe room to reach gaskets, seals, and other inner parts. In this post, we’ll look at why flange spreaders matter, how they work, and the different jobs that call for them.

The Critical Role in Industrial Joint Maintenance

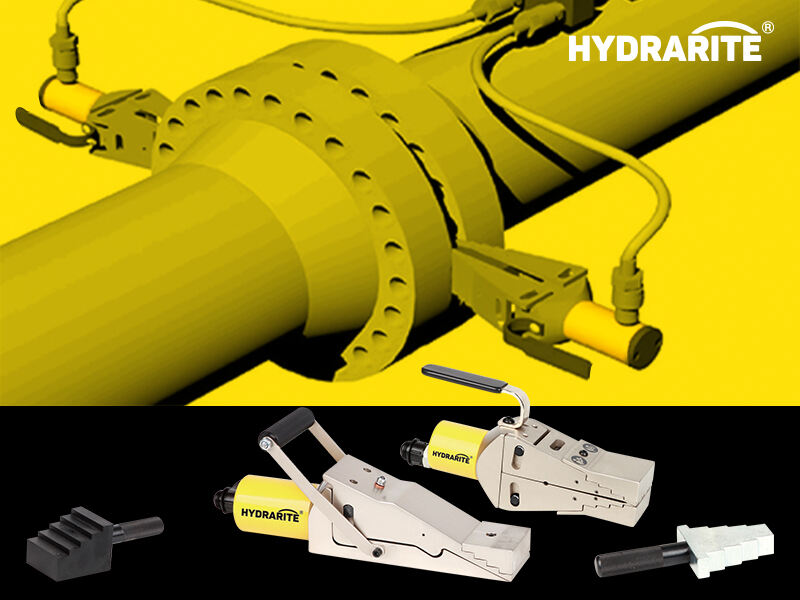

Spreaders shine where pipes meet. From oil drills to chemical plants to power stations, flanged joints show up just about everywhere. When staff need to check, swap, or fix a gasket nestled inside, they usually run into tight, rusted surfaces. Trying to shove the flanges apart with a hammer or a pry bar might bend metal, crack seals, or-far worse-injure a worker. Flange spreaders solve that by using steady pressure to open the joint cleanly and slowly. This controlled approach ensures that the integrity of the flanged connection is maintained, preventing unnecessary damage that could lead to costly repairs or operational disruptions. Whether it's a small leak in a chemical pipeline or a major issue in a power plant's steam system, flange spreaders provide the precision needed to access the inner components without causing further harm.

Safety: The Cornerstone of Flange Spreader Design

Safety comes first on any shop floor, and a good flange spreader really helps keep everyone out of harm's way. Instead of forcing two flanges apart with a crowbar-an effort that can suddenly release built-up pressure or send heavy bits swinging-maintenance teams can work calmly with a spreader. Modern models have anti-slip jaws and even pressure controls, so the gap opens evenly and no one gets pinched or startled. Additionally, many flange spreaders are equipped with overload protection mechanisms. These mechanisms automatically stop the spreading process if the pressure exceeds a safe limit, preventing sudden failures that could result in serious accidents. The ergonomic design of the handles also reduces the risk of strain injuries for workers, even during extended use.

Versatility Across Industrial Landscapes

That's not the only plus. Spreaders are sold in dozens of sizes, from slim units for chill-water pipes to beefy sets made for refinery headers, so crews grab the same tool set no matter where they work. That mix saves time during changeovers, cuts the need to hunt for adapters, and keeps jobs moving forward while the clock-and budget-tick on. Some advanced models even come with interchangeable jaws, allowing them to adapt to different flange types and sizes with minimal effort. This versatility makes them indispensable in industries where equipment varies greatly, such as in large manufacturing facilities that handle multiple types of piping systems.

Extending Equipment Lifespan Through Proper Maintenance

Beyond keeping work sites safe and flexible, flange spreaders actually help machines live longer. Flanged joints need regular care to stop leaks that can cause big repair bills and lost production time. When technicians slide a spreader into the gap, they can swap gaskets the right way and line up the plates before tightening. Small moves like that protect the whole system and push back the day when heavy equipment has to be pulled from service. By ensuring that gaskets are replaced correctly and flanges are properly aligned, flange spreaders reduce the wear and tear on the entire system. This, in turn, extends the intervals between major overhauls, saving companies significant amounts of money in the long run.

Adapting to the Evolving Industrial Maintenance Landscape

Industries are changing fast, and with that, the need for smart, reliable maintenance tools keeps climbing. Watching equipment through sensors and data means more automatic shut-offs and guided repairs, which lifts the pressure on operators. Flange spreaders fit right into that picture, giving them a steady place in modern shops. Companies that grab these high-precision tools today will stay ready for tomorrow's tougher maintenance tasks and keep their lines running at top speed. As industries move towards more predictive and preventive maintenance strategies, flange spreaders will continue to play a vital role. Their ability to provide precise and controlled spreading makes them compatible with the data-driven approach to maintenance, ensuring that repairs are done accurately and efficiently based on real-time equipment monitoring.

In conclusion, flange spreaders are more than just tools; they are essential components in ensuring safe, effective, and efficient maintenance operations across various industries. Their ability to provide controlled spreading, enhance safety, adapt to different situations, extend equipment lifespan, and fit into modern maintenance practices makes them a key investment for any company looking to keep its operations running smoothly.