When it comes to wiring up homes, offices, or bigger projects, speed and reliability rule. Crimping tools have settled into the spotlight because they cut down preparation time and lift the quality of every bond. In the paragraphs that follow, we’ll walk through the types of crimpers out there, what makes them matter, and how each can push a job forward-whether the work is done by a seasoned pro or a weekend DIYer.

The Core Mechanism: Uniting Wires and Connectors Seamlessly

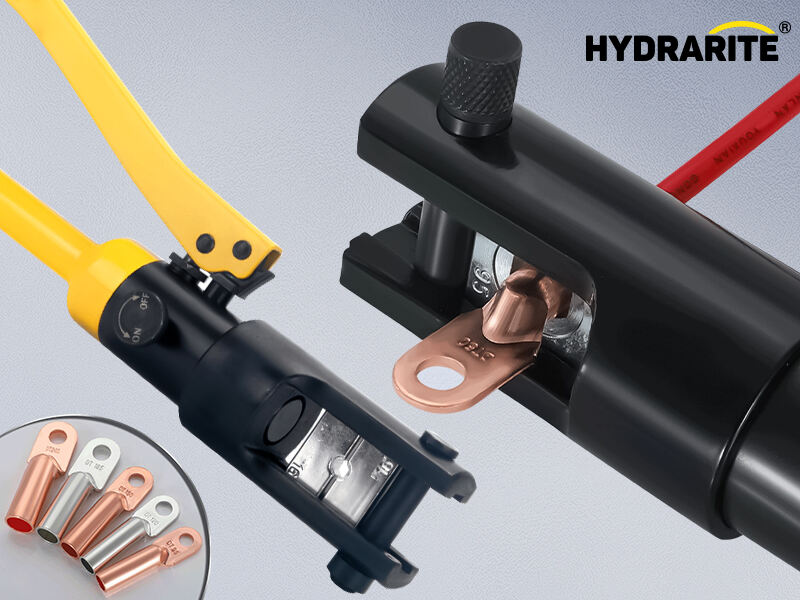

At its core, a crimping tool squeezes metal parts together so wire and connector become one solid unit. The market now offers a choice between simple hand versions, powerful hydraulic models, and quick electric options, letting you pick the right tool based on job size and detail. For a few cables in a home theater, a handheld crimper works great; on a factory floor where hundreds of lugs must slip into place, a hydraulic or battery-driven model saves time and spares wrist strain. These tools are engineered with precision jaws that match specific connector sizes, ensuring a uniform crimp every time. This consistency eliminates the guesswork that often comes with manual wiring methods, making even complex connections feel straightforward.

Efficiency Redefined: Speeding Up Electrical Installations

The biggest time-saver crimpers deliver is how quickly they work. Soldering takes patience, heater setup, and a steady hand, and even the best joinery can still crack under stress. Crimping, on the other hand, clicks closed with one firm squeeze, and nearly anyone can learn that motion in minutes. Finish more connections in less time, and the whole project shrinks, pushing costs down and profit up for those who make a living doing installs. In large-scale projects like commercial buildings or industrial facilities, this speed difference adds up dramatically. A team using crimping tools can complete wiring tasks in half the time it would take with traditional methods, allowing them to take on more projects or allocate resources to other critical aspects of the job.

Reliability That Stands the Test of Time

Crimping tools give you a quick and durable way to join wires. When a terminal is crimped the right way, it can shrug off engine vibrations, heat cycles, and other stresses you find on the bumper or production line. That kind of dependability really matters in sensitive areas like cars, heavy machinery, or aircraft, where a loose connection can create safety risks or force a costly repair stop. Unlike tape, which can degrade over time, or solder, which may develop cracks, a properly crimped connection forms a gas-tight seal that resists corrosion and oxidation. This longevity reduces the need for rework and maintenance, further boosting overall efficiency.

Technological Advancements: Making Crimping Smarter

Tool makers know these jobs pay the bills, so they keep upgrading crimpers. Many mid-range models now let you dial in the wire gauge, flash a pressure read-out, or even show a green pass-light when the crimp is done. Such features turn a hand operation into a repeatable, confidence-building task. Looking further ahead, factory-grade automatic crimp lines with robots or smart sensors promise even tighter tolerances and higher throughput for high-volume builds. These smart tools can also store data on each crimp, providing a digital record of quality control that’s invaluable for compliance in industries like aerospace and healthcare, where strict regulations govern electrical installations.

Versatility Across Projects: From DIY to Industrial Scale

Taken together, heavy-duty crimpers boost speed, cut scrap, and improve reliability across the board. For teams who wire anything from junction boxes to drivetrains, swapping quick connectors beats fumbling with solder or tape. Keeping up with the growing world of powered, guided, and cloud-linked crimping gear is therefore a simple way to save time, protect reputations, and stay ahead of competitors. Whether it’s a homeowner installing a new lighting fixture or a contractor wiring an entire office complex, there’s a crimping tool designed to handle the task efficiently. This versatility ensures that crimping tools remain an essential part of any electrical toolkit, regardless of the project’s size or complexity.

In summary, crimping tools have revolutionized electrical installations by combining speed, reliability, and technological innovation. Their ability to create strong, long-lasting connections quickly makes them indispensable for professionals and DIY enthusiasts alike. As technology continues to advance, crimping tools will only become more efficient, further enhancing their role in the world of electrical work.