The manufacturing industry is always changing and looking for ways to keep processes and operations as efficient as they possibly can be. Pressing tools are essential in improving waste in production, enhance quality, and add value in production processes. This article goes deeper into the ways pressing tools enhance manufacturing processes, the different categories of pressing tools, and how modern innovations are changing the industry.

What Are Pressing Tools?

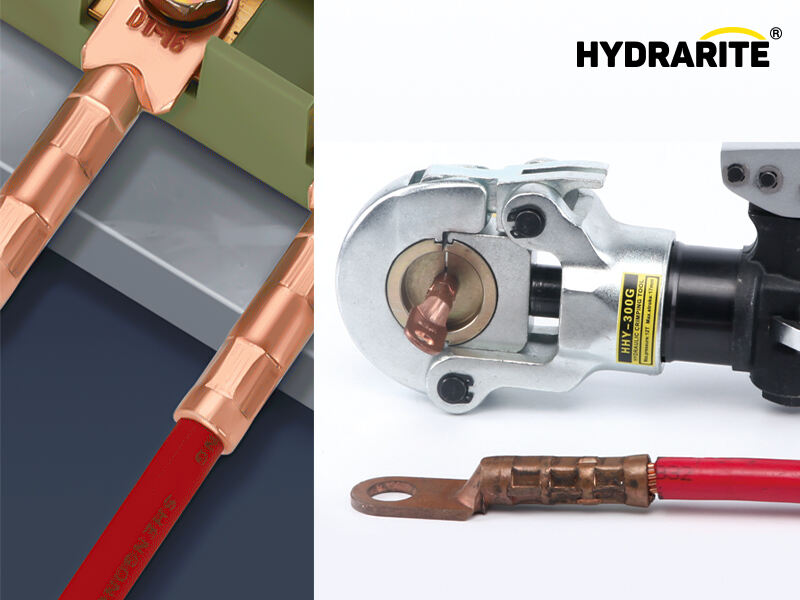

Also referred to as stamping tools, pressing tools are mechanical tools which serve to shape materials, primarily metals, using pressure. Pressing tools are important for different types of manufacturing processes such as automotive, aerospace, and consumer products. These tools help manufacturers achieve desired dimensions and quality and are important in meeting market requirements as well.

Increasing Production Efficiency

The most remarkable value of pressing tools is the speed at which they can enhance production processes. Unlike in traditional machining, which takes time to produce parts, pressing tools enable production of large quantities of parts in a very short time. Thanks to rapid production, manufacturers can meet tight deadlines and respond promptly to dealing changes in the customer’s needs. For example, pressing tools in the automotive industry aid in the production of hundreds of thousands of components every day which helps keep the assembly line well stocked.

Lessening Material Waste

Scrap material can be minimized through progressive die stamping which boosts the efficiency of pressing tools. In today’s environmentally conscious market, sustainable manufacturing practices are becoming more and more critical. Therefore, saving money on raw resources is a major plus. The ability to recycle and reuse materials ensures the production process is as efficient as possible.

Enhancing the Manufacturing Quality

The pressing tools make significant contributions to the manufacturing process quality control. With these tools, each part can be manufactured with precision which complies with the strict quality control policies. In addition, the uniform pressure throughout the process aids in consistent dimensional control and reduces the chance of defects. Reliability is critical in industries such as aerospace which depend on precision and is sensitive to defects.

Pressing Tools and Their Relationship with Technological Development

Just like any other industry, the pressing tools industry is also experiencing technological modernization. Sanding machines with new features like automation, smart features, and self-regulation are changing the pressing tools industry. Equipment like pressing machines and other pressing tools integrated with automation features along with sensors can also supervise and control the processes. In addition, advanced technologies like Artificial Intelligence can aid in improving predictive maintenance.

Changes in the Industry and How It Impacts the Future

Pressing tools have now become an indispensable part of the modern pressing technologies. Sanding machines with new features like automation, smart features, and self-regulation are changing the pressing tools industry. Equipment like pressing machines and other pressing tools integrated with automation features along with sensors can also supervise and control the processes.

To conclude, pressing tools come with a variety of features, such as improving efficiency, quality, and sustainable features. The pressing machine industry serves as a new and enhanced way to promote advanced technologies to sharpen the opportunities available to businesses and other users.