Metal fabrication shops and heavier production lines all rely on bending machines. From car chassis to aircraft wings, each structure starts life on the flat. Modern bending equipment saves hours of hand work, turning sheet and plate into parts that fit together perfectly. In this post, we'll break down the main types of bends, show where each style shines, and look at the smart tech that keeps pushing the field forward.

The Core of Metal Bending: Press Brakes and Their Precision

Press brakes, as many people still call them, sit at the heart of the bending process. By applying steady pressure along a die, they fold metal sheets to almost any angle. Precision is non-negotiable: one degree off can ruin a hundreds-of-parts order. Shops choose between hydraulic, mechanical, or electric models, and each variant comes with clear strengths.

Diverse Types of Bending Machines: Strengths for Every Need

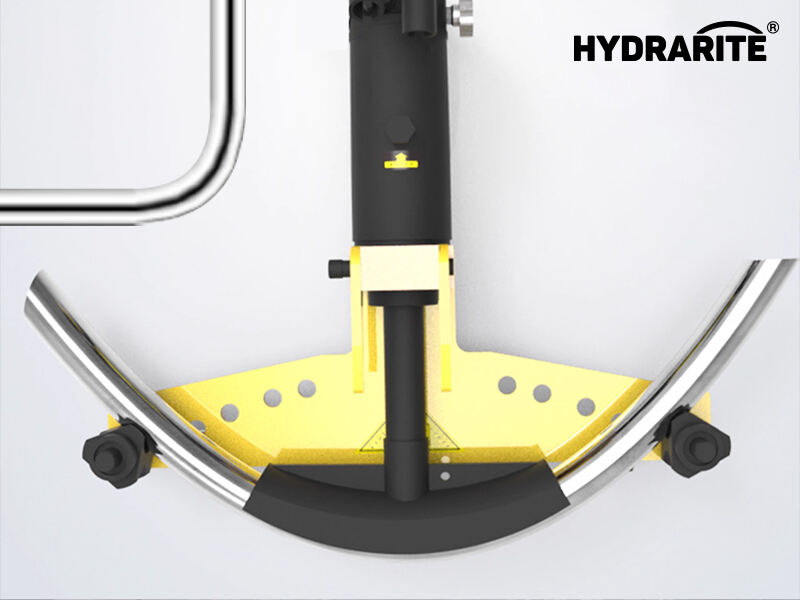

Hydraulic bending machines are famous for their muscle and flexibility. With their steady force, they bend thick plates and twist tricky angles without breaking a sweat. That power is why construction sites and shipyards keep them nearby whenever heavy metal work comes up. They can handle materials like high-strength steel and aluminum alloys with ease, making them indispensable in industries where durability is paramount. Mechanical press brakes, in contrast, win points for speed. Because the punch-and-release cycle is quick, these machines shine on production lines that demand lots of parts in very little time. Their consistent performance ensures that mass production runs smoothly, meeting tight deadlines. Electric press brakes enter the scene as a younger option, yet their calm energy use and razor-sharp controls appeal to forward-thinking shops looking to save power while still getting precise bends. They are ideal for operations where energy efficiency and fine-tuning are top priorities.

Wide-Ranging Applications: From Heavy Industry to Creative Projects

The bending machines hobby kit stays busy, showing up in all sorts of projects. Car factories depend on them for frames, brackets, and exhaust pipes that have to fit together perfectly. The precision of these machines ensures that every component works in harmony, contributing to the safety and performance of vehicles. Planes rely on similar set-ups in aerospace lines, turning sheets into light but strong parts that help engines fly efficiently. The ability to create complex shapes with high strength-to-weight ratios is crucial in the aerospace industry. Beyond heavy industry, smaller shops use these tools to fold metal legs for furniture, bend sheet covers for home appliances, and even shape panels for cool art displays. That blend of brute strength and delicate control makes a good press brake feel right at home in nearly every workshop, enabling creativity and functionality in various products.

Technological Advancements: Smart Tech Driving the Industry Forward

Modern bending machines are changing fast, thanks largely to new technology. When CNC-computer controls are added, bends that used to rely on the operator's skill can now be done with almost the same accuracy every time. Those controls let a person set up complex bending steps in advance, which cuts mistakes and speeds up work on the shop floor. On top of that, fresh software tools and light AI make it possible to see wear before it slows production, so scheduled maintenance can be planned instead of guessed. This predictive maintenance helps reduce downtime and keeps the machines running at peak performance.

Market Trends: Adapting to Growing Demands

Private orders for one-off or tightly shaped metal parts keep climbing, pushing the bending-machine market upward. In response, builders are making models that accept faster changeovers and can be easily reconfigured for different jobs. This flexibility allows manufacturers to quickly adapt to varying customer needs. The move toward greener plants also matters; many firms now use lighter frames, recycle scrap on the line, and design drives that sip power rather than gulp it when the machine is idle. These eco-friendly initiatives not only reduce the environmental impact but also help businesses save on energy costs.

Overall, bending equipment is giving metal shops the tools they need to hit deadlines without losing quality. If businesses adopt the latest versions now, they will be ready for the even harder challenges the next decade brings. Investing in smart, efficient benders is more than a cost-it's a way to protect margins and earn new customers, ensuring long-term success in the ever-evolving metal fabrication industry.

Table of Contents

- The Core of Metal Bending: Press Brakes and Their Precision

- Diverse Types of Bending Machines: Strengths for Every Need

- Wide-Ranging Applications: From Heavy Industry to Creative Projects

- Technological Advancements: Smart Tech Driving the Industry Forward

- Market Trends: Adapting to Growing Demands